Flipcab Cable Pvt. Ltd.

A Place Where Standard Wires & Cables are Born.

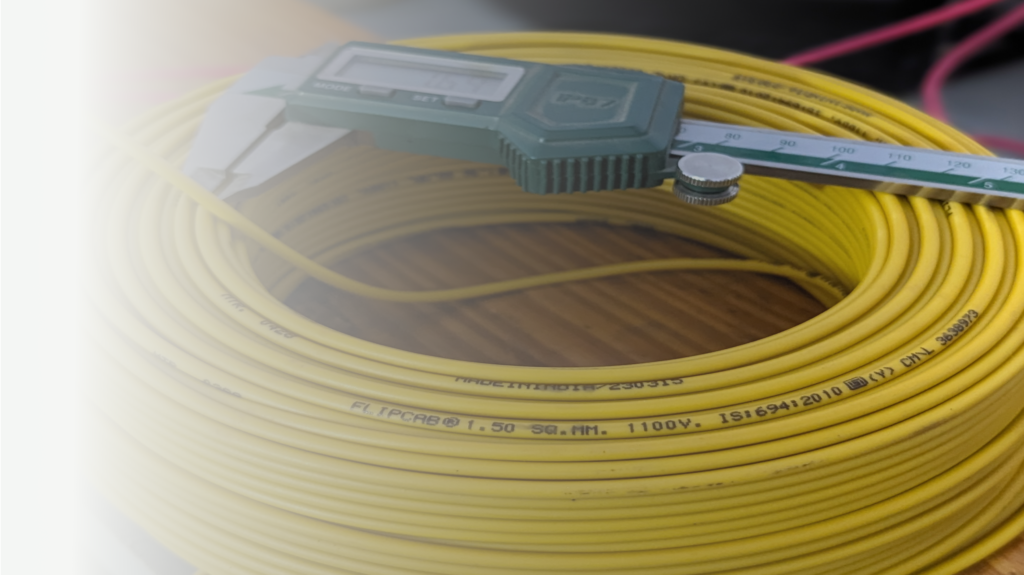

Key Differences Between

Do and Don’t Wire

Do

Dont’s

Do ensure proper cable installation by following manufacturer guidelines and industry standards to maintain optimal performance and safety

Don’t overload cables by exceeding their rated current or voltage capacities, as this can lead to overheating, insulation breakdown, and potential fire hazards.

Do regularly inspect cables for signs of wear, damage, or deterioration, and promptly address any issues to prevent potential hazards or disruptions.

Don’t expose cables to extreme temperatures, moisture, corrosive substances, or mechanical stresses beyond their specified limits, as this can compromise their performance and lifespan.

Do use cable management solutions, such as cable trays, conduits, or cable ties, to organize and protect cables, minimizing the risk of damage and ensuring ease of maintenance.

Don’t use damaged or frayed cables, as they can pose safety risks and impair electrical conductivity, potentially leading to equipment malfunction or electrical accidents.

Do consider the voltage, current, and environmental conditions when selecting cables, ensuring they are suitable for the intended application and can handle the expected loads and operating conditions.

Don’t mix cables of different types, ratings, or specifications within the same circuit, as this can lead to compatibility issues, increased resistance, and compromised electrical performance.

Do implement proper grounding and bonding techniques to ensure electrical safety and mitigate the risk of electrical faults or surges

Don’t neglect regular cable inspections and maintenance, as this can lead to undetected issues, reduced reliability, and increased safety risks.

Do label and document cable connections and configurations for easier identification, troubleshooting, and maintenance purposes.

Don’t use improper cable routing or bend radii that exceed recommended limits, as this can cause cable deformation, insulation damage, and increased risk of short circuits.

Do engage qualified and trained professionals for cable installation, maintenance, and repair tasks to ensure compliance with safety standards and industry best practices

Don’t overlook the importance of fire safety in cable selection. Avoid using non-flame-retardant cables in applications where fire resistance is crucial, such as buildings or high-risk environments.